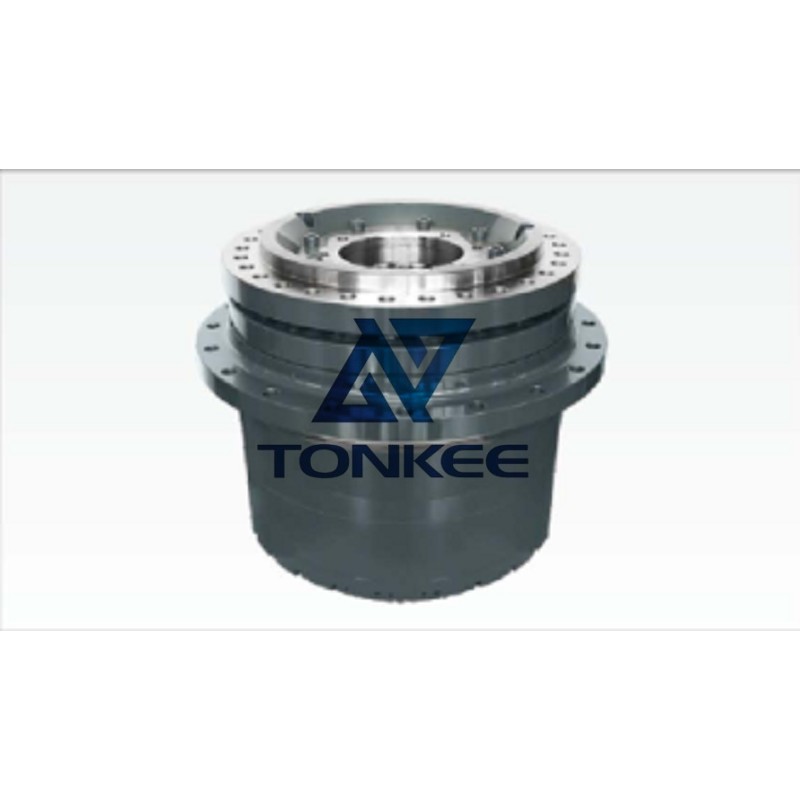

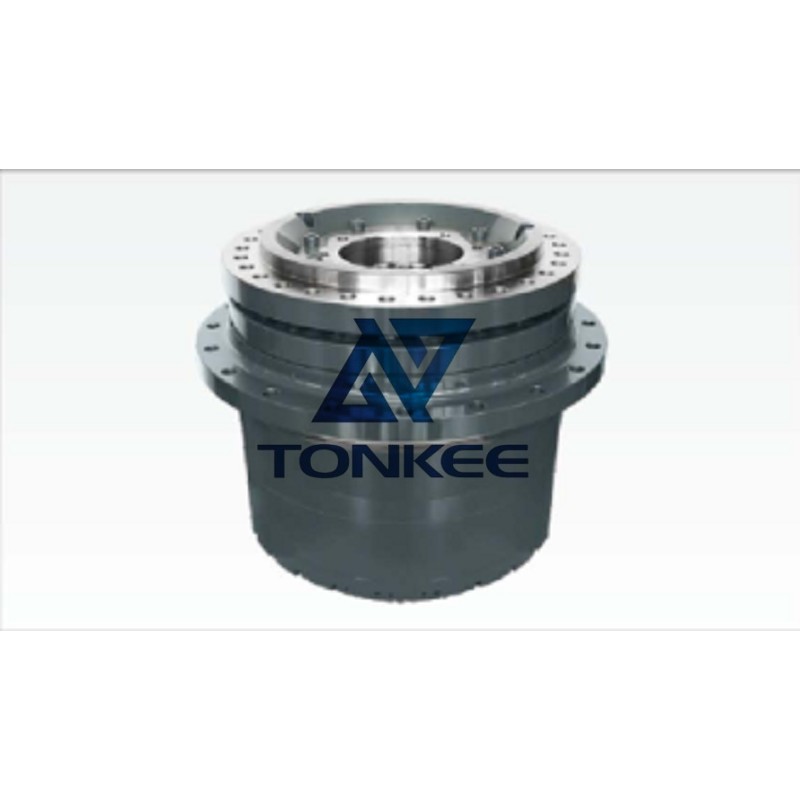

The 715 drive gearbox is renowned for its robust construction and high performance.

It is engineered to handle heavy loads and operate in demanding environments, making it suitable for a wide range of applications. The gearbox is crafted with precision using quality materials to ensure durability and longevity.

One of the notable features of the 715 drive gearbox is its versatility. It is available in various configurations, allowing for customization to specific requirements. This flexibility enables the gearbox to adapt to different applications, such as trucks, buses, construction equipment, and industrial machinery.

The gearbox incorporates advanced gear technology to optimize power transmission. It utilizes a combination of gears, shafts, and bearings to achieve efficient torque conversion and speed control. The gear ratios are carefully designed to provide the desired balance between speed and torque, allowing for smooth operation and optimal performance.

To ensure reliable operation, the 715 drive gearbox is equipped with a robust lubrication system. Adequate lubrication is essential for reducing friction and heat generation, extending the lifespan of the gearbox. The gearbox is designed to facilitate easy maintenance and oil changes, minimizing downtime and maximizing productivity.

Safety is a paramount concern in any industrial setting, and the 715 drive gearbox addresses this aspect comprehensively.

It incorporates multiple safety features, including overload protection and fail-safe mechanisms. These features help prevent damage to the gearbox and other components in the event of excessive load or system failure.

The 715 drive gearbox also focuses on energy efficiency. By minimizing power losses through optimized gear design and reduced friction, it helps improve overall system efficiency. This, in turn, leads to reduced fuel consumption and environmental impact, making it an environmentally friendly choice.

Furthermore, the 715 drive gearbox is designed with noise reduction in mind. Noise and vibration dampening technologies are employed to minimize operational noise levels, providing a quieter working environment and enhancing user comfort.

English

English Türkçe

Türkçe