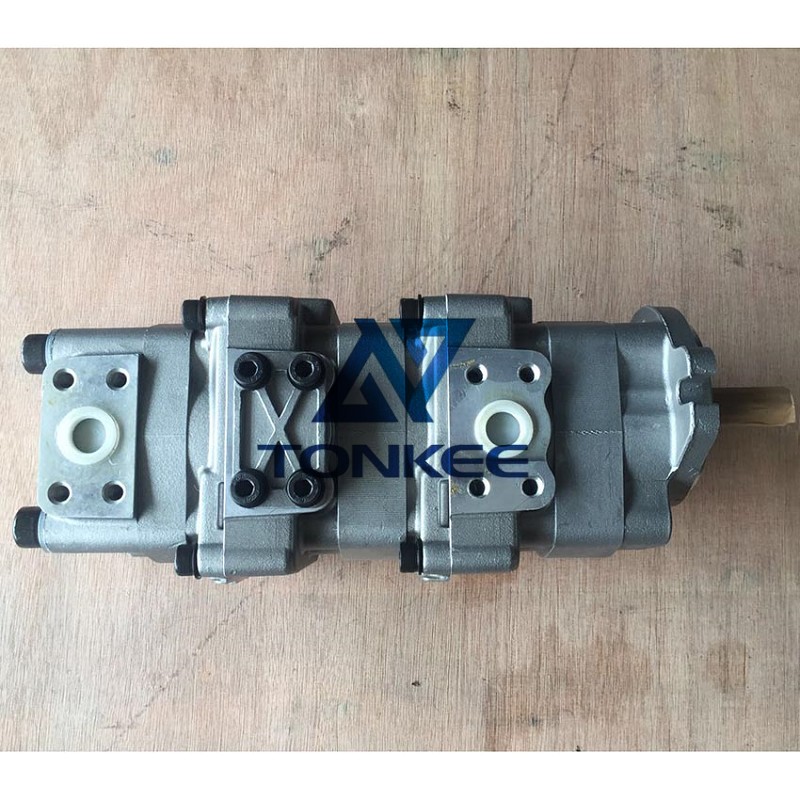

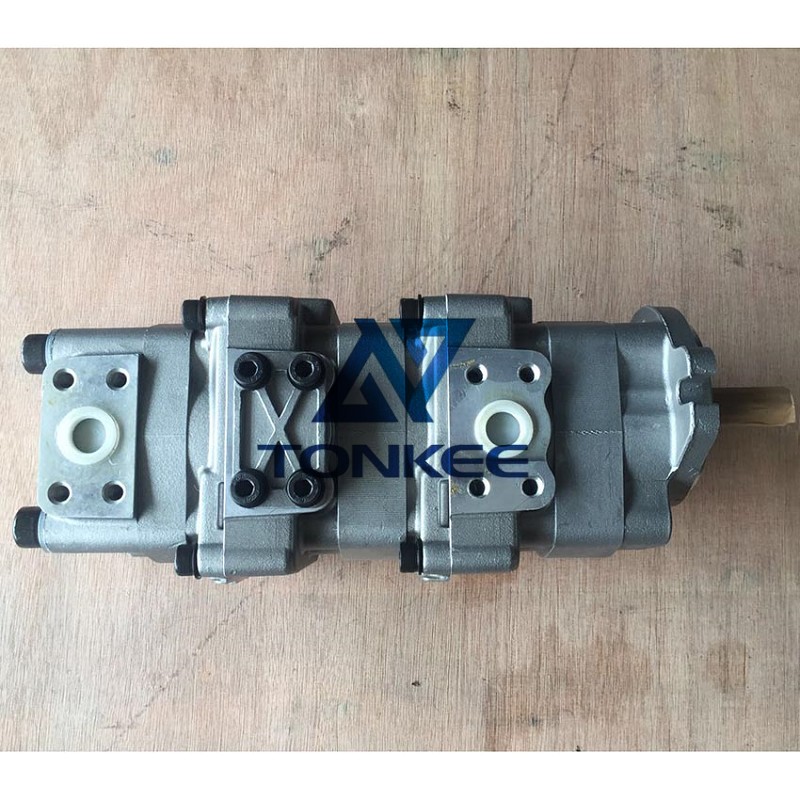

One of the key features of the Komatsu 40 original triple pump is its triple pump configuration.

This configuration consists of three separate pumps, each responsible for a specific function. The first pump is the main pump, which delivers high-pressure hydraulic fluid to power the machine's primary functions such as lifting, digging, and pushing. The second pump, known as the pilot pump, supplies hydraulic fluid at a lower pressure to control various auxiliary functions and assist in the overall operation of the equipment. Finally, the third pump, called the gear pump, is responsible for providing lubrication to the system, ensuring smooth operation and reducing wear and tear on the components.

The triple pump design offers several advantages. Firstly, it allows for efficient power distribution, ensuring that each function receives an adequate supply of hydraulic fluid to operate optimally. This results in improved performance, increased productivity, and reduced energy consumption. Additionally, the use of separate pumps for different functions enhances system reliability. If one pump fails, the other pumps can continue to operate, minimizing downtime and allowing for continued operation with reduced functionality.

The Komatsu 40 original triple pump boasts impressive specifications that contribute to its exceptional performance.

It has a maximum operating pressure of [insert pressure value] and a flow rate of [insert flow rate value]. These specifications make it suitable for a wide range of heavy-duty applications, including excavators, bulldozers, wheel loaders, and more. The pump is also equipped with high-quality components, such as precision-machined gears and durable bearings, which ensure reliable and long-lasting operation even in harsh working conditions.

Furthermore, the pump features advanced control mechanisms to optimize its performance. It incorporates a pressure compensator that adjusts the pump's output based on the load requirements, ensuring consistent and efficient operation. The pump also includes various safety features, such as pressure relief valves and filters, to protect the system from excessive pressure and contaminants, thereby extending its lifespan and reducing maintenance needs.

Maintenance of the Komatsu 40 original triple pump is relatively straightforward. Regular inspection and maintenance of the pump, including checking for leaks, cleaning filters, and replenishing hydraulic fluid, are necessary to ensure its optimal performance and longevity. It is recommended to follow the manufacturer's guidelines and schedule routine maintenance at specified intervals.

English

English Türkçe

Türkçe