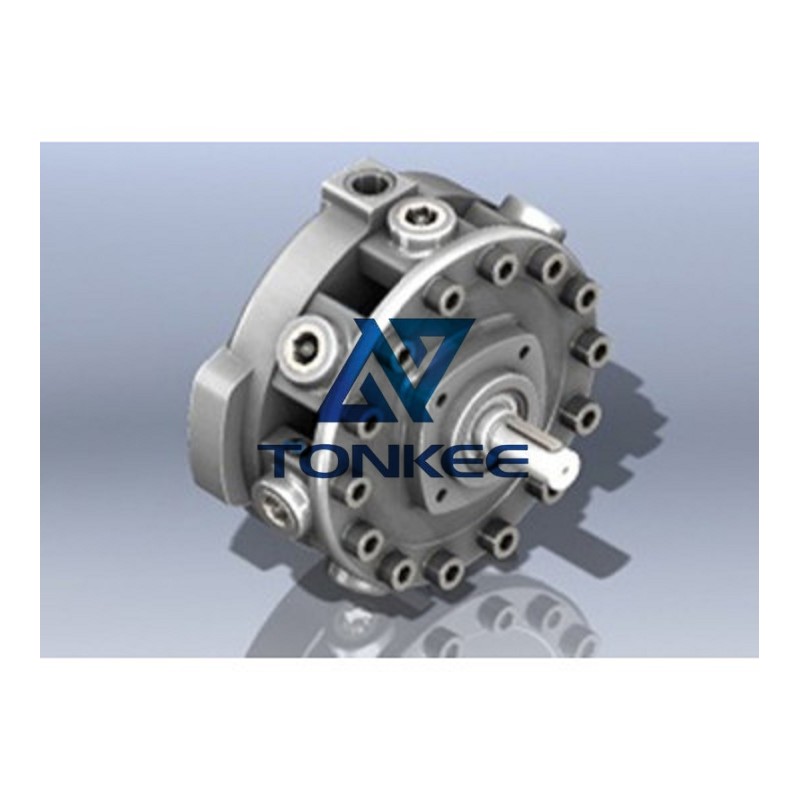

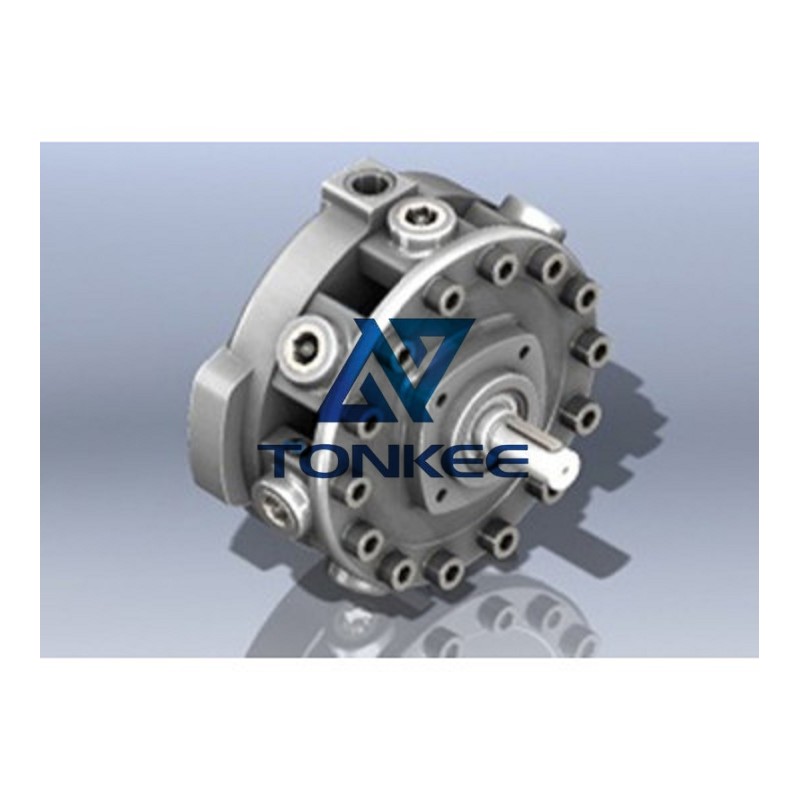

The 11R5 Polyhydron Radial Piston Pump features a robust construction with a compact design, making it suitable for installations where space is limited.

It is built with high-quality materials to ensure durability and longevity even in demanding operating conditions. The pump's components are precision-engineered to deliver optimal performance and minimize energy loss.

This radial piston pump operates based on the principle of radial pistons arranged around a central drive shaft. Each piston is connected to the drive shaft through a connecting rod, which enables the pistons to reciprocate radially within the pump housing. The movement of the pistons creates a pumping action, drawing in hydraulic fluid through the pump inlet and discharging it through the pump outlet.

The 11R5 pump is designed to handle a wide range of hydraulic fluids, including mineral oils, synthetic oils, and fire-resistant fluids. It has excellent suction characteristics, allowing it to operate efficiently even with low inlet pressures. The pump is also capable of delivering high pressures, typically up to 350 bar (5000 psi), making it suitable for applications requiring significant power.

One of the key advantages of the 11R5 Polyhydron Radial Piston Pump is its precise and consistent flow control.

It is equipped with an adjustable swash plate mechanism that allows the user to regulate the pump's output flow rate. This feature enables the pump to adapt to varying system requirements, providing flexibility in different applications.

The pump's efficiency is further enhanced by its low internal leakage and advanced sealing technology. These characteristics minimize energy losses and improve overall system performance. The pump's compact size and lightweight design also contribute to its efficiency, as it reduces the amount of space required for installation and minimizes inertia.

The 11R5 Polyhydron Radial Piston Pump is suitable for a wide range of applications, including machine tools, construction machinery, material handling equipment, hydraulic presses, and industrial automation systems. Its high-pressure capabilities make it ideal for powering hydraulic cylinders, actuators, and motors.

Proper maintenance is crucial to ensure the longevity and performance of the pump. Regular inspections, including checking for any signs of wear, leaks, or contamination, are recommended. It is also important to follow the manufacturer's guidelines for lubrication and fluid cleanliness.

English

English Türkçe

Türkçe